Latest Blog

Save time and money with Minster’s Pattern Shop

From concept to design to finished product, get it all at Lawton Minster. Our Minster location has an in-house pattern shop and plenty of pattern storage for all of your tooling needs. Welcome to our Pattern Shop “Minster has had an in-house pattern shop for many, many years,” said plant manager Steve Johnson. The pattern…

C.A. Lawton has 2 Locations To Better Serve You

De Pere, Wisconsin

MINSTER, OHIO

C.A. Lawton has 2 Locations To Better Serve You

De Pere, Wisconsin

MINSTER, OHIO

What We Do

Large Iron Casting

On-site. We specialize in large iron casting in the 500lb - 20,000lb range.

Our Minster, OH location is capable of casting gray and ductile iron up to 45,000lbs.

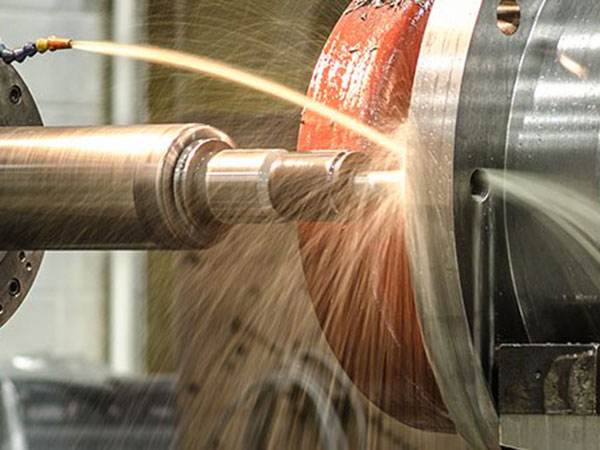

Machining

On-site. We simplify the casting process by providing castings machined on-site and sourced through our trusted supplier partners.

Why Choose Us?

Single Source Accountability

While many foundries offer a range of abilities, few offer the full array of services on-site. We provide on-site pattern, casting, machining, testing, and assembly capabilities.

The synergy of remarkable people, processes, and all services under one roof, gives our clients all the benefits of single-source accountability.

5 Generations

We are a 5th generation foundry-centered manufacturer and truly integrated supplier. We’ve learned the importance of listening to our client's needs and developing strong relationships built on exceptional communication.

Remarkable People

We encourage and develop our employees to be involved and empowered, inspiring them to turn plans into action. From engineers and manufacturing specialists to accounts payable and customer advocates. Our people are remarkable.

Prepare for your visit to Lawton De Pere by watching our safety video

Recent Blogs

Recent Blogs

Save time and money with Minster’s Pattern Shop

From concept to design to finished product, get it all at Lawton Minster. Our Minster location has an in-house pattern shop and plenty of pattern storage for all of your tooling needs. Welcome to our Pattern Shop “Minster has had an in-house pattern shop for many, many years,” said plant manager Steve Johnson. The pattern…

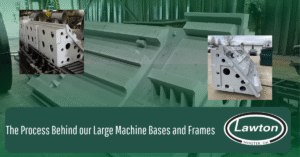

Read MoreThe Process Behind Our Large Machine Bases and Frames

The C.A. Lawton Co. in Minster is your place to turn for large machine bases or frames. Our facility is mastering these large iron castings and meeting our customers’ expectations. We recently delivered several large machine bases weighing over 17,000 pounds. Why Choose Minster for your Large Machine Bases and Frames? Our Minster facility specializes…

Read MoreC.A. Lawton renews Green Tier 2 Status

The C.A. Lawton Co. in De Pere, WI was the first foundry in Wisconsin to earn the DNR’s Green Tier 2 status. And now, C.A. Lawton is continuing that superior environmental performance by renewing our Tier 2 participation. What is the Green Tier 2 Program? The Wisconsin Department of Natural Resources started the Green Tier…

Read MoreFlame-Resistant Clothing Keeping Workers Safe

The C.A. Lawton Co. is dedicated to keeping our workers safe. This is why we recently tested some flame-resistant protective gear to see which ones would work best in our foundry. Going through Cintas, C.A. Lawton chose t-shirts, long-sleeve shirts, coveralls and jeans that will help protect our workers, while still offering comfort and flexibility.…

Read MoreSpecializing in Large Machine Bases

C.A. Lawton Minster knows how to handle large orders. We’re talking about 17,000-pound orders, like this recently completed machine base. Minster was tasked with producing this giant casting, with overall dimensions of 144″ x 68″ x 66″. The total weight of this machine base was 17,200 pounds. And this wasn’t just a block of iron…

Read MoreThe C.A. Lawton Co. Joins the Sustainable Business Council

We are proud to announce that C.A. Lawton in De Pere is now a member of the Sustainable Business Council in Wisconsin. The membership shows our continued commitment to be involved in sustainability efforts at Lawton to make the community we live in better. What is the Wisconsin Sustainable Business Council? The Wisconsin Sustainable Business…

Read More